PlantView® Predictive Maintenance

Download Brochure

Operations & Maintenance (O&M) costs represent the greatest expense in owning

and operating a facility over its life cycle. In the past, the approach to reducing

budgets has been to reduce O&M costs. However, this often results in fewer available

resources to maintain the facility. An unintended consequence may be cost increases

from unexpected equipment failures. By viewing O&M as an opportunity to improve

performance, instead of as a cost line item, facilities can:

Operations & Maintenance (O&M) costs represent the greatest expense in owning

and operating a facility over its life cycle. In the past, the approach to reducing

budgets has been to reduce O&M costs. However, this often results in fewer available

resources to maintain the facility. An unintended consequence may be cost increases

from unexpected equipment failures. By viewing O&M as an opportunity to improve

performance, instead of as a cost line item, facilities can:

Effective maintenance programs use a blend of corrective, preventive and predictive maintenance strategies to improve reliability in a cost-effective manner. Maintenance Optimization is the process of developing the appropriate balance for the facility. Typically, it involves moving an existing maintenance program from a corrective approach where maintenance is performed as a result of unexpected failures, or a preventive approach where maintenance is performed on a scheduled basis, to a planned approach where the required maintenance is performed at the most optimum time.

The PlantView Predictive Maintenance module (PlantView/PdM) is the key to a planned maintenance approach. PlantView/PdM applies diagnostic technologies to plant equipment to evaluate the present operating condition of the equipment prior to a scheduled maintenance outage. It has the goal of determining specific maintenance requirements, including whether the equipment will operate reliably until the next scheduled outage or if maintenance will be needed at that time. If maintenance is required, PdM helps determine what specific steps are necessary.

PlantView/PdM facilitates a condition-based approach to maintenance by collecting and storing diagnostic technology results, facilitating the analysis of multiple technologies into an overall assessment of the equipment and making the results accessible to a broad group of staff to support maintenance decisions. PlantView/PdM can help you set up and run a predictive maintenance program at your facility.

Benefits

- Makes data accessible across the enterprise to a wide variety of users.

- Maintains authoritative listing of all equipment in the PdM Program.

- Facilitates establishing and maintaining an “Equipment and Condition Indicator” (E&CI) matrix. This matrix cross-references equipment with their diagnostic technologies and establishes the frequency of collecting data.

- Provides a listing of scheduled work (collecting data and assessing equipment) required to implement the defined PdM Program.

- Facilitates and speeds the data entry process to ensure value-added information and insights are recorded.

- Improves transparency and facilitates historical analysis and data mining.

- Provides displays that summarize diagnostic data, enabling quick determination of equipment conditions.

- Maintains a “Condition Status Report” (CSR) matrix representing a visual summary of the overall equipment condition.

- Provides many views, listings and reports of the collected data and equipment condition to keep all users informed of the latest equipment health at a facility.

- Monitors adherence to the defined PdM Program.

Features

- Stores all information in a centralized, structured Oracle database.

- Search function enables query of historical information to aid technical staff with troubleshooting and operational analysis.

- Fully user configurable to match facility hierarchy. Users define plant systems, diagnostic technologies and the equipment participating in the PdM Program.

- Completely customizable security model to control various level user access and privileges in the system.

PlantView/PdM Process Flow

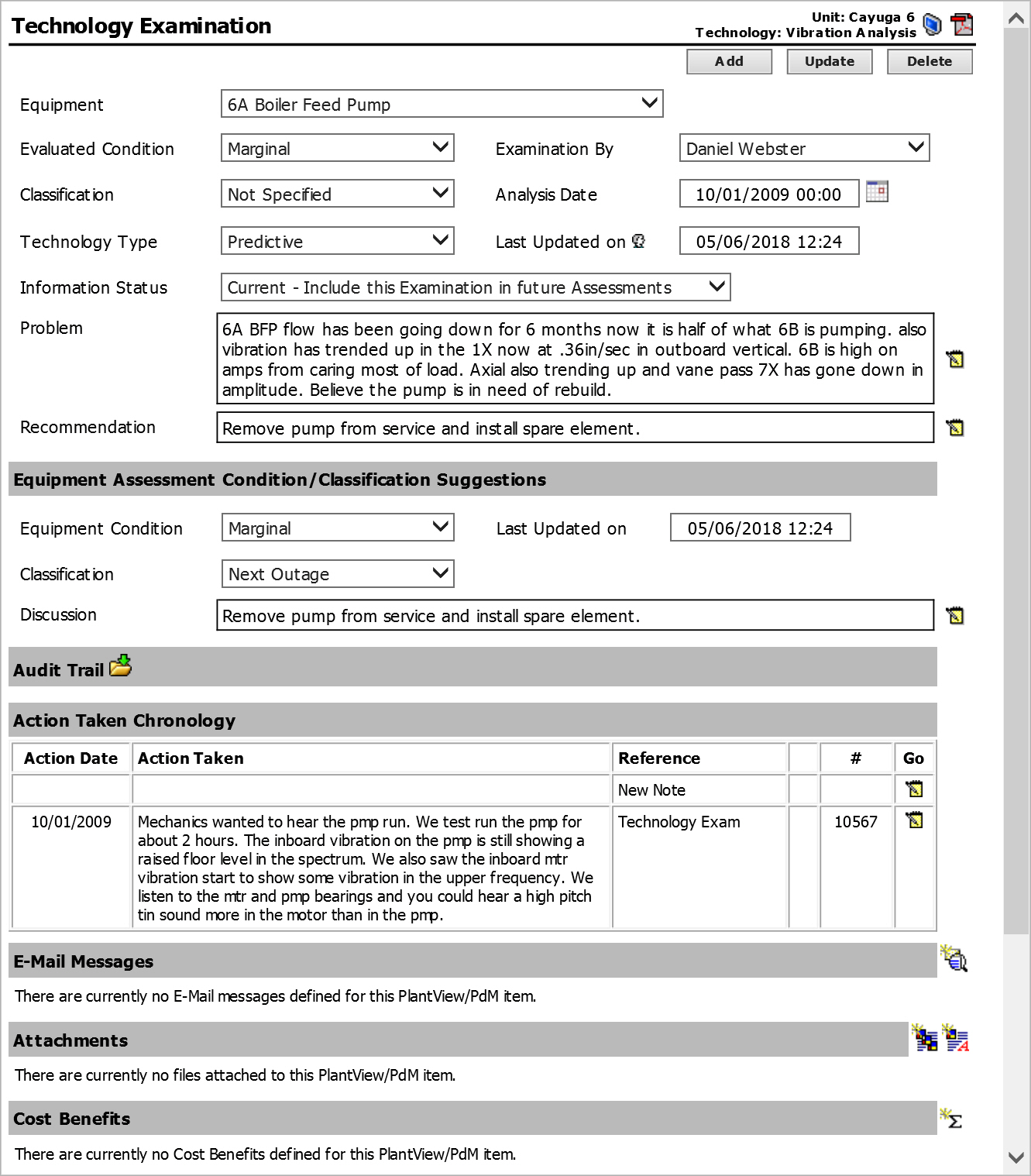

On a periodic basis, a trained technician collects data concerning the health of their equipment and enters this information into PlantView as a Technology Exam. Each entry includes an evaluated condition, a summary of any problems, appropriate analysis and a series of recommendations.

Technology Exams also contain detail items such as Action Taken Chronology, E-Mail and Attachments. The Action Taken Chronology is a sequence of actions resulting from the Exam. E-Mail allows the technologist to notify an individual of their findings and to include a URL link. Attachments allow files such as pictures, documents or spreadsheets to be uploaded, providing additional information or documentation.

Multiple technology exams are performed for each component – reflecting the different diagnostic tools available such as vibration, thermography, leak detection or lubricant analysis.

A companion desktop application and web services are available to directly import technology exam data from outside test results or on-line systems with a minimum of effort.

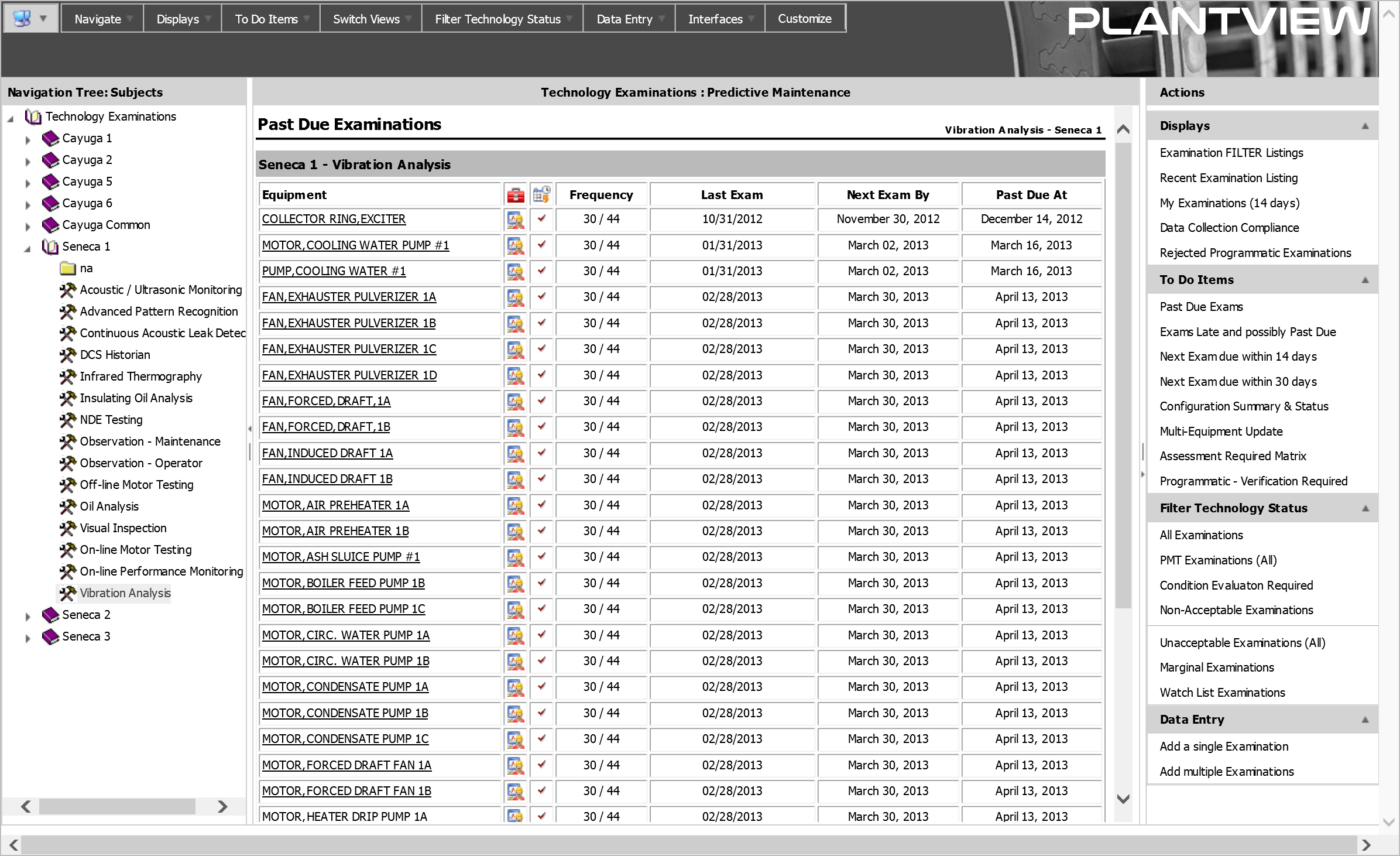

For predictive maintenance to be successfully employed, all necessary information is gathered on a regular basis. The data is analyzed for signs of equipment degradation or incipient failures. Appropriate corrective action can be taken in response to the indications provided by the diagnostic systems. PlantView contains summary displays tracking the status of the data collection.

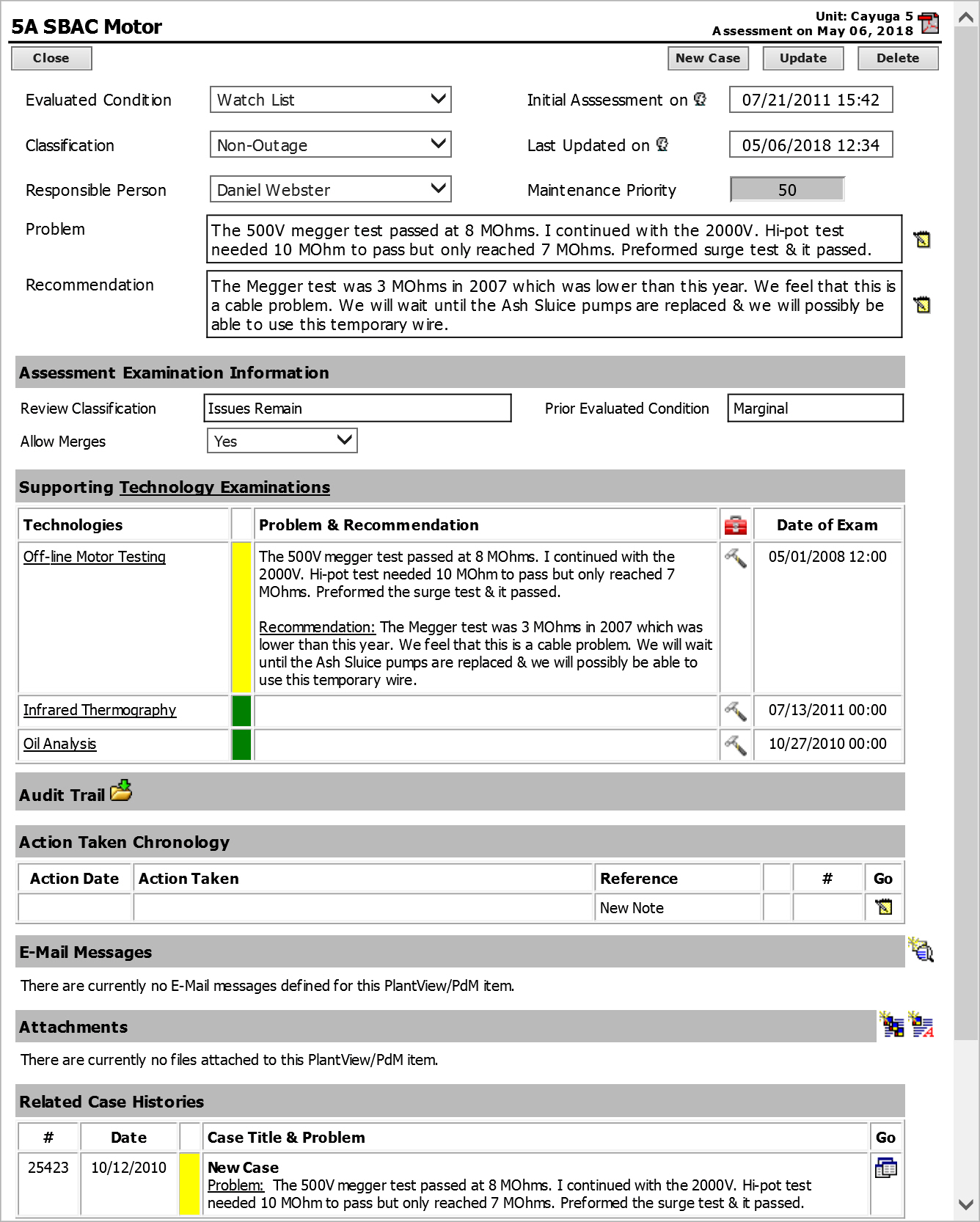

When the information collection has been completed, a System Owner or Subject Matter Expert reviews the recommendations of the trained technicians and forms an integrated opinion, also known as an Equipment Assessment. Equipment Assessments are typically performed monthly.

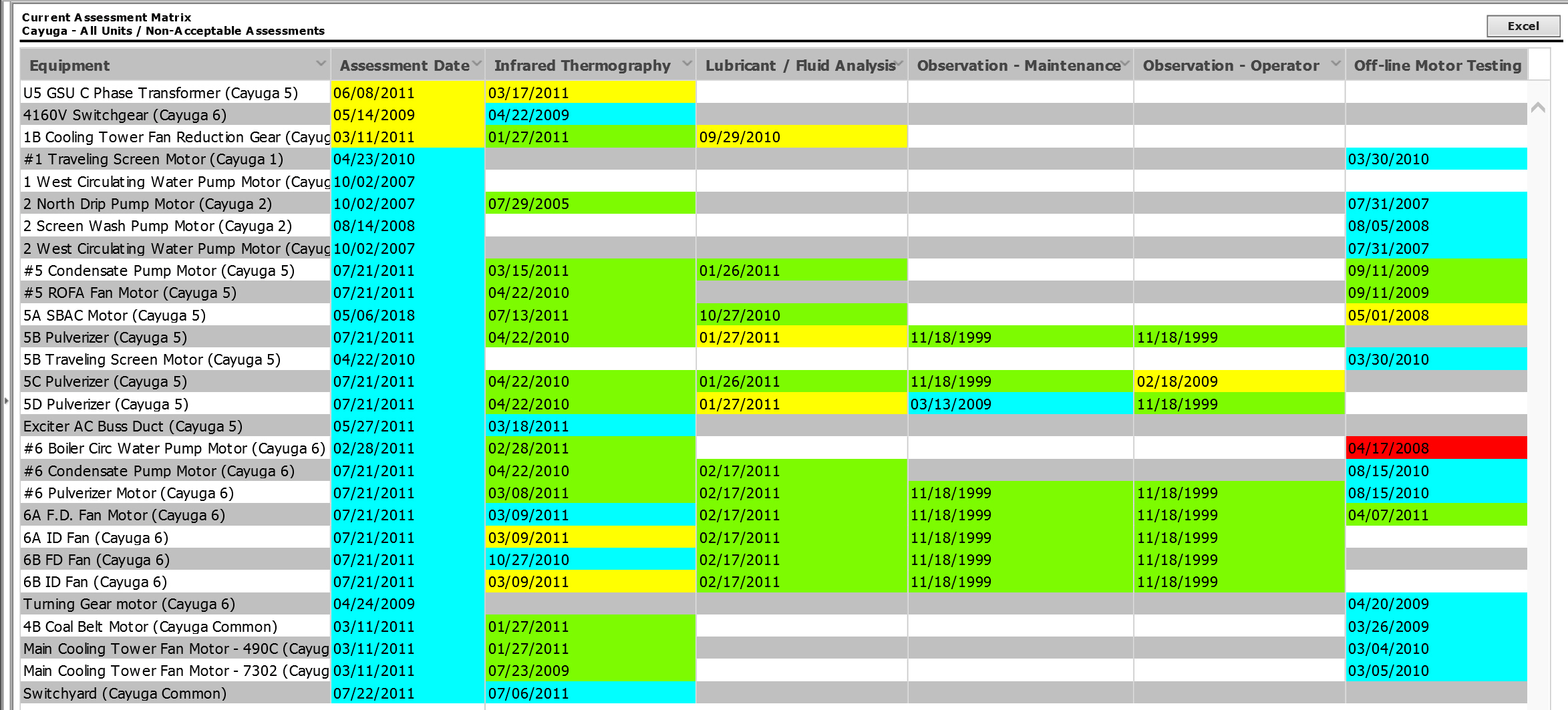

For a quick read of the overall equipment health of a facility, all the Equipment Assessments can be viewed together in a condition status matrix which combines the equipment conditions with their respective supporting technologies.

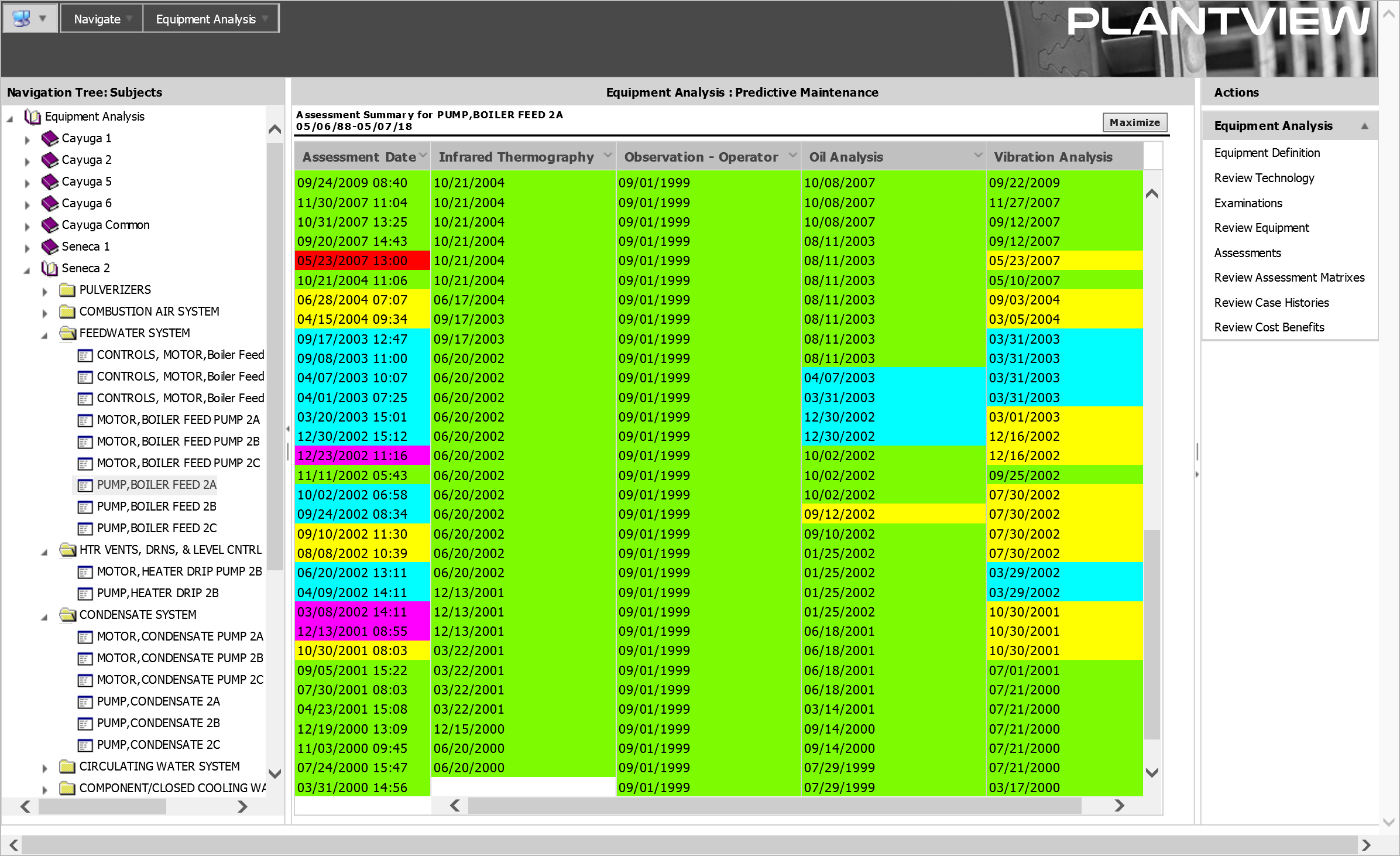

Equipment Assessments can be searched to locate patterns of maintenance problems on a single piece of equipment or a group of similar equipment. It is also possible review the changes in equipment condition over time with a matrix display that lists all the equipment assessments, with their supporting technology exams, for a user defined historical period.

When a significant problem is detected, the Technology Exams and Equipment Assessments are assigned to a Case History. Actions are tracked, and pertinent information is added as attachments to the folder. As maintenance is performed and the case is closed, the Case History is archived to support future maintenance decisions.

Configuration Details

The PlantView Predictive Maintenance module is used to collect, analyze and communicate condition monitoring results within an organization. On a periodic basis, a trained technician collects data concerning the health of their equipment and enters this information into PlantView as a Technology Exam. Each entry includes an evaluated condition, a summary of any problems, appropriate analysis, a series of recommendations and any supporting data. Multiple technology exams are performed for each component – reflecting the different diagnostic tools available such as vibration, thermography, leak detection or lubricant analysis. A companion desktop application and web services are available to directly import technology exam data from outside test results or on-line systems with a minimum of effort.

For predictive maintenance to be successfully employed, all necessary information is gathered on a regular basis. The data is analyzed for signs of equipment degradation or incipient failures. Appropriate corrective action can be taken in response to the indications provided by the diagnostic systems. PlantView contains summary displays tracking the status of the information collection. When the information collection has been completed, a System Owner or Subject Matter Expert reviews the recommendations of the trained technicians and forms an integrated opinion, also known as an Equipment Assessment. Equipment Assessments are typically performed monthly.

For a quick read of the overall equipment health of a facility, all the Equipment Assessments can be viewed together in a condition status matrix which combines the equipment conditions with their respective supporting technologies. Equipment Assessments can be searched to locate patterns of maintenance problems on a single piece of equipment or a group of similar equipment. It is also possible review the changes in equipment condition over time with a matrix display that lists all the equipment assessments, with their supporting technology exams, for a user defined historical period.

When a significant problem is detected, the Technology Exams and Equipment Assessments are assigned to a Case History folder. Actions are tracked, and pertinent information is added as attachments to the folder. As maintenance is performed and the case is closed, the Case History is archived to support future maintenance decisions.